Piece Part Manufacturer

Robotic Solution for Tube Bending

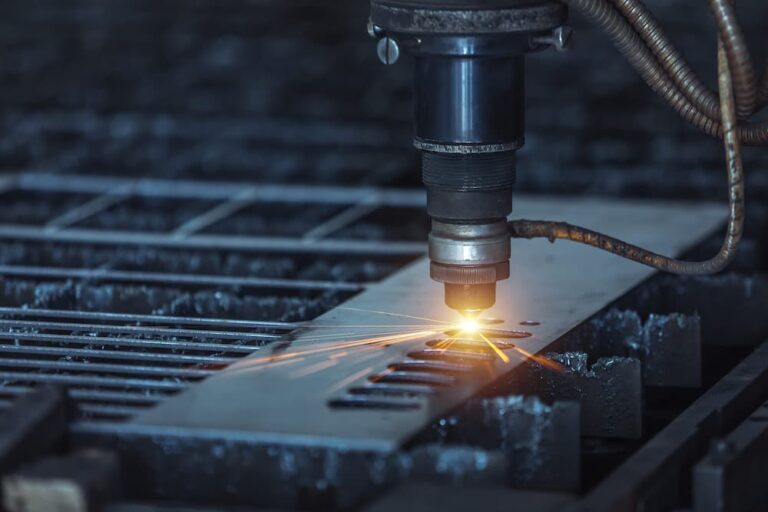

Integra Teknomate designed and installed this industry award winning quad Intech robot machine tending automation cell used for tube bending in a 1+ million square foot facility.

Intech Robot’s robotic solution helped this manufacturer significantly increase daily production output, reduce their labor costs, improve piece part quality and provided a robotic automation system capable of operating three (3) shifts per day with minimal operator control and support.

Discover how Intech Robots can design and install your robotic solution. Contact us today to talk about the future of your company: +91 98208 08944

Goals of Automation

“Made in India”

India manufacturing continues to gain strength, but there is no rising tide to lift every boat. Defending what you’ve got while seizing new opportunities requires escalating levels of manufacturing efficiency and flexibility.

That’s where we come in. Integra builds robotic solutions for managing and growing your business. We’ve been delivering turn-key robotic solutions, along with a full range of technical and support services, since 1996. Our mission is your success.

Automation Solution & Benefits

The four Intech Robots were integrated with a custom tube seam finding station designed by Integra Teknomate, two new BLM tube benders, two customer furnished tube flattening presses, two Intech Robots custom designed inspection stations and four “hot swap” material handling cart stations designed by Intech Robots.

Each cart has 100 storage locations and material handlers can move carts in & out of the cell without stopping the robots during production. The inspection stations can measure up to 21 conformance characteristics for each completed tube.

Intech Robots has successfully implemented solutions for industries across the board over the last 20 years. Contact us today and get started on the future of your business: +91 98208 08944 .