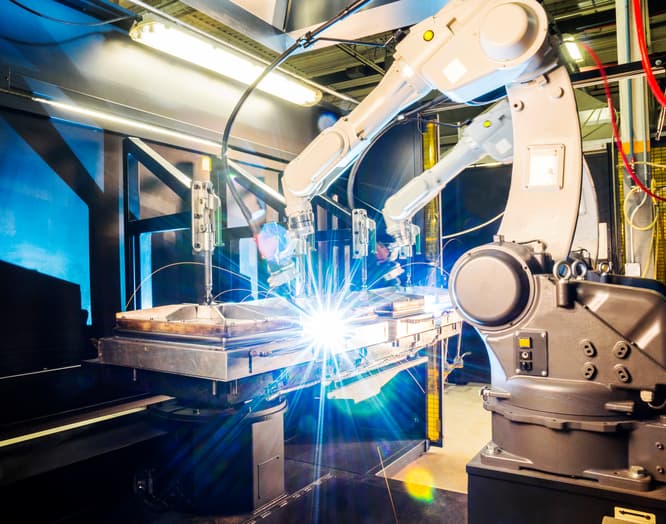

Robotic Welding Cell

Increased Production, Safety & Quality

Why Integrated Robotic Welding Cell?

Robotic welding is one of the most common robotic applications in the industrial sector, being driven mainly by the automotive sector for the last several decades. Robotic welding is most productive when completing high-volume, repetitive welding tasks.

With robotic welding integration, you can:

With robotic welding integration, you can:

- Decrease Employee Risk to Burns & Hazardous Fumes

- Increase Quality & Consistency of Welds

- Decrease Time Required to Finish The Job

- Decrease Space Needed to Perform Tasks

- Decrease Labor Costs

Robotic Robotic welding Systems

Ask any seasoned welder what the key is to a successful weld is and they will most likely tell you a steady hand and hands-on experience. What is more steady and consistent than taking the welding process out of human hands and instead turning it into an automated process making welds consistent, accurate and repeatable every time? Boost your efficiency and increase production with robotic welding systems.

“Made in India”

India manufacturing continues to gain strength, but there is no rising tide to lift every boat. Defending what you’ve got while seizing new opportunities requires escalating levels of manufacturing efficiency and flexibility.

That’s where we come in. Intech Robots builds robotic solutions for managing and growing your business. We’ve been delivering turn-key robotic solutions, along with a full range of technical and support services, since 1996. Our mission is your success.

An electric arc between an electrode and metal base produces an intense heat to melt and intermix two parts. Arc welding is used for applications calling for high accuracy and repeatability.

A current is passed between two metal pieces of metal, a pool is formed by the resulting heat, and the two pieces are joined together. Resistance welding is the most economical form of robotic welding and is best for heat-treating projects.

A type of resistance welding, spot welding joins thin metals that resist electrical currents. It’s typically used in the automotive industry to join sheet metal frames together.

TIG welding is used when precision is of the utmost importance, while MIG is best for applications where system simplicity and speed are desirable.

Automated Laser Welding & Cutting Robots

A laser generator delivers via a fiber optic cable a laser light through a robotic cutting head to weld pieces together. Laser welding, including remote laser welding for hard to reach weld locations, is often used in high volume applications that require high accuracy.

Laser cutting is commonly used in the trimming of manufacturing parts across multiple industries. Robotic laser processing is currently being employed to improve productivity and processing flexibility. Putting these robots to work in your facility will give you the proper foundation for growth.

Contact us today and get started on the future of your business: +91 98208 08944 .

Laser cutting is commonly used in the trimming of manufacturing parts across multiple industries. Robotic laser processing is currently being employed to improve productivity and processing flexibility. Putting these robots to work in your facility will give you the proper foundation for growth.

Contact us today and get started on the future of your business: +91 98208 08944 .

Automated Laser Welding & Cutting Robots

Plasma welding involves ionized gas passing through a copper nozzle to produce extremely high temperatures. Plasma arc welding is used when flexibility is required, as velocity and temperatures can be easily adjusted.

A plasma cutter will use electrically conductive gas to transfer energy from a power supply to any conductive material, resulting in a cleaner, faster cutting process.

This is one of many enhanced robotic solutions you can integrate into your facility with Intech Robots.

A plasma cutter will use electrically conductive gas to transfer energy from a power supply to any conductive material, resulting in a cleaner, faster cutting process.

This is one of many enhanced robotic solutions you can integrate into your facility with Intech Robots.